The Petrochemical Supply Chain and Erdos Miller

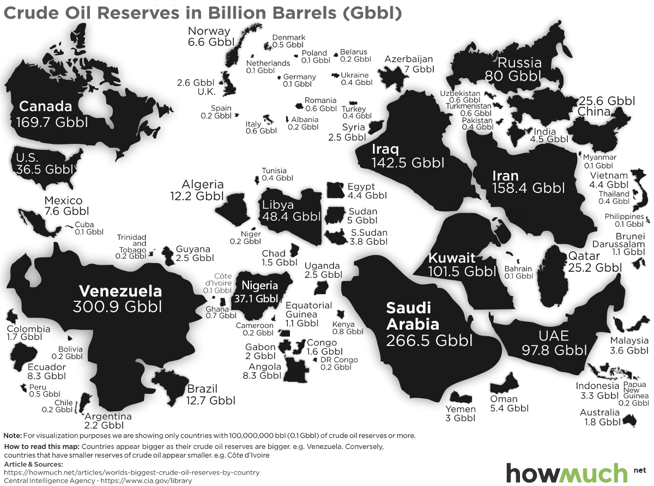

Oil is a resource that is of particular interest to every reasonably-organized faction of humanity.

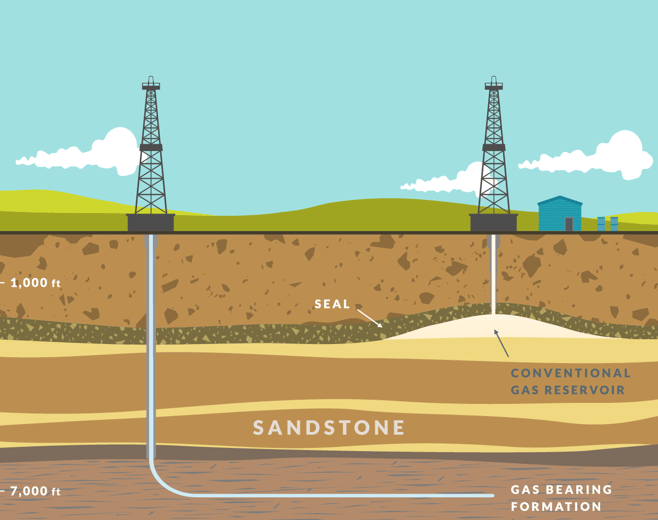

Crude Oil is located in sedimentary layers of rock. Yes, Crude Oil is a proper noun here. Remains of plants and animals have been converted to crude oil deposits by extreme heat and pressure that is exerted by additional layers of rock forming on top of the remains. Because crude oil is less dense than water, it eventually flows through porous rock and is trapped below impermeable layers of rock. The oil will remain underneath these impermeable layers, waiting to be discovered. Geologists are hired to locate crude oil deposits.

The traditional survey method that geologists employ in finding oil is that of physical examination of a rock formations' features. To acquire a sample for such examination, drilling and excavation is usually necessary. Modern methods include the use of gyroscopes to detect gravitational differences that can be attributed to oil flow, electronic detection of the smell of crude oil, and the creation of shock waves that are sent through the ground and reflected back up to the surface. If a potential source of oil is found, the location is marked, and the geologists move onto their next survey.

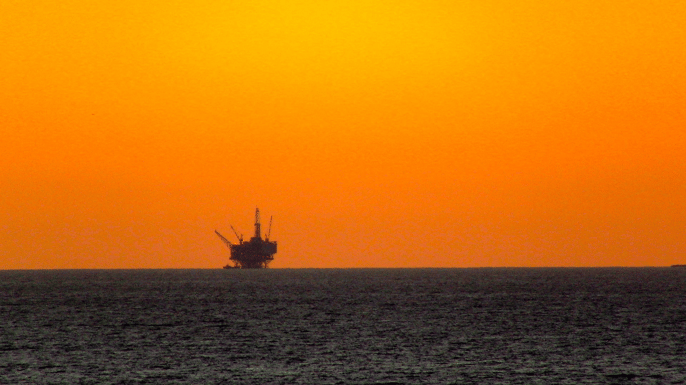

After the geologists mark a potential well, a prospective drilling company orders environmental scientists to further determine the boundaries of the oil reserve and decide if the surrounding environment demands additional studies. Pending the determination of the scientists, a rig will be deployed onto the oil reserve.

The commissioning oil company will then proceed to make accommodations for the operations of a new drilling rig by building roads, sourcing water, and building a reserve pit. With smaller and independent operations, this work is typically contracted out. Vertically integrated companies use sub-divisions to construct their rigs. Regardless of what company is running the operations, next comes both figurative and literal tons of trucks.

The Infrastructure of Petrochemical

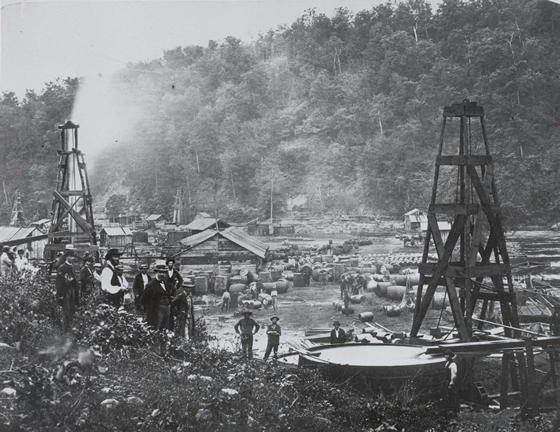

Finding Oil

Crude Oil is located in sedimentary layers of rock. Yes, Crude Oil is a proper noun here. Remains of plants and animals have been converted to crude oil deposits by extreme heat and pressure that is exerted by additional layers of rock forming on top of the remains. Because crude oil is less dense than water, it eventually flows through porous rock and is trapped below impermeable layers of rock. The oil will remain underneath these impermeable layers, waiting to be discovered. Geologists are hired to locate crude oil deposits.

The traditional survey method that geologists employ in finding oil is that of physical examination of a rock formations' features. To acquire a sample for such examination, drilling and excavation is usually necessary. Modern methods include the use of gyroscopes to detect gravitational differences that can be attributed to oil flow, electronic detection of the smell of crude oil, and the creation of shock waves that are sent through the ground and reflected back up to the surface. If a potential source of oil is found, the location is marked, and the geologists move onto their next survey.

After the geologists mark a potential well, a prospective drilling company orders environmental scientists to further determine the boundaries of the oil reserve and decide if the surrounding environment demands additional studies. Pending the determination of the scientists, a rig will be deployed onto the oil reserve.

The commissioning oil company will then proceed to make accommodations for the operations of a new drilling rig by building roads, sourcing water, and building a reserve pit. With smaller and independent operations, this work is typically contracted out. Vertically integrated companies use sub-divisions to construct their rigs. Regardless of what company is running the operations, next comes both figurative and literal tons of trucks.

The Trucks

All equipment, commodities, and personnel to and from rigs are mainly moved by trucks and infrequently, helicopters or airplanes. Oilfield trucks can be divided into two categories: Flatbed and Heavy Haul trucks. Flatbed trucks operate within road-legal weights and dimensions.

Flatbed trucking typically involves semi-trucks that transport equipment, personnel, commodities, soil, salt or freshwater for rig use, potable water for crews, gravel, drill string components, explosives, vacuum machines, fracking sand, and fuel.

Heavy haul trucks move rig components that require operation outside of legal transportation weights and dimensions. Pole trucks, winch trucks, and heavy haul flatbeds belong to this category. Forklifts and cranes are on-site to unload or load trucks and many trucks carry assistants referred to as 'swampers'. Trucking companies also support mechanical, dispatching, sales, legal, and administration staff.

The rig will be constructed as equipment makes its way to the rig site. Once the rig is ready, drilling can begin.

Rig Operations

On land, drilling rig crews generally consist of two sets of six people working 12-hour shifts. After the rig crew, the crew that directly supports the rig includes a drilling engineer, two drilling helpers, and a supervisor known as a tool pusher. The indirectly supporting crew includes a chemist, two chemist helpers, and two rig managers. The rig maintenance crew contains six people led by a maintenance engineer. Offshore rigs may employ more people, even up to 200 on the largest offshore rigs.

There are two conventional methods of drilling a well: vertical drilling and horizontal drilling.

Vertical drilling is the conventional style of drilling and describes the method of drilling wells straight down. Horizontal, or directional drilling, is the practice of drilling non-vertical wells by altering the angle of the drill as it progresses through the ground. Recent advances in technology have seriously brought down the cost of directional drilling, making it more than competitively cost-effective. The key advantages of directional drilling are the ability to avoid sensitive environments, the ability to drill into offshore wells onshore, the ability to drill several wells from one location, and the de facto ability to get more oil from the same well. Erdos Miller primarily targets the directional drilling market.

How Can Erdos Miller Assist Directional Drillers?

Directional Drillers want to get their drill string over to the oil in the shortest amount of time with the lowest possible cost. In order to get somewhere, you need to know where you want to go and where you are going from. From there you can draw a line, and if only it were that simple. In order to get from where the drill bit is now to where that oil is, you need to know where the bit is without being able to see it. Dead Reckoning is a navigation system in which the traveler first determines their direction in relation to the target and then advances without any corrections until the traveler stops.

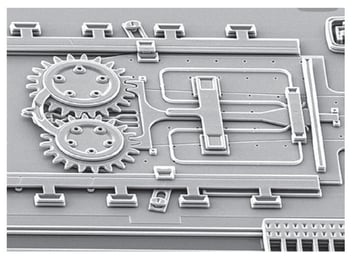

With the corresponding knowledge of how far and in what directions the bit has traveled we can model its path. In the same manner that you don’t hold the wheel of a car completely still when you drive, the drillers will make corrections to their path as they progress. In this endeavor, the success or failure of your operation relies on the accuracy of the Directional Module, a sensor suite that can tell you in what direction your drill string is pointing.

Erdos Miller MicroPulse

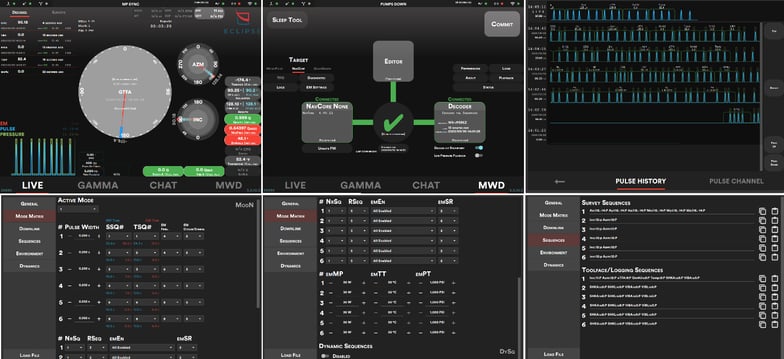

MicroPulse 2 and 3 are directional modules. They measure magnetic and gravitational forces on the X, Y, and Z as they relate to the tool’s positioning. This “Six-Axis” data is used to calculate its own the Inclination and Azimuth, thereby a 3D direction and of the drill bit by extension. MP2 and MP3 can transmit through CAN, qMix, and MudPulse telemetry, with pulse-width capabilities ranging from 1.0s to 0.1s. A complete set of calibration measurements are taken at several temperatures to more accurately map the behavior of the tool in response stressful environments and a ridiculously reliable tool is the result.

The primary difference between MicroPulse 2 and MicroPulse 3 is that MP2 is rated for 135˚C, while MP3 is rated for 150˚C. The most noticeable difference between MP2 and MP3, and other directional modules is their sizes. An industry competitor’s directional module, providing what amounts to be the same measurements as MicroPulse with relatively similar capabilities, measures out to be 29.2”. MicroPulse 2 and MP3 come in a 16” and 19” chassis respectively.

Azimuthal Gamma Controller

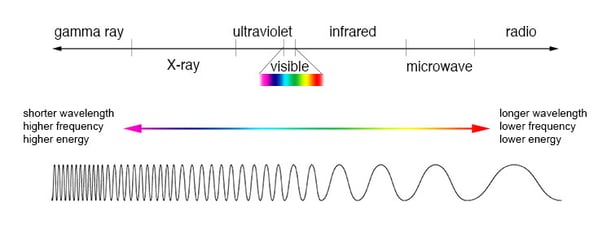

Many subterranean rock formations emit radiation as a result of radioactive decay of atomic nuclei contained in the rock. The electromagnetic particles emitted can be observed on the ‘Gamma’ side of the electromagnetic spectrum, containing the particles with the highest energy and smallest wavelengths.

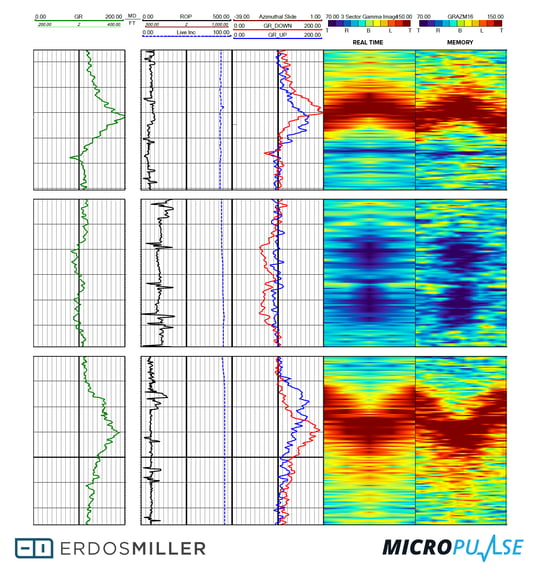

A specific need for the collection and interpretation of Gamma levels in determining when the bit enters or exits a formation. By applying a deductive process and understanding the categorization of what rocks typically emit what levels of radiation, it is possible to make an educated guess on how to proceed with the drill string in order to get to that oil. In short, the nature of the gamma emissions surrounding the string can be used to determine where best to go for oil.

The Azimuthal Gamma Controller interfaces with devices that detect gamma radiation. A high-resolution image of the surrounding gamma radiation is generated while the string spins, borrowing from the concept of radar.

New Problem: The inclusion of a Directional Module and Azi-Gamma system increases the length of the sensor package of the drill string. Also, these two or more devices must now communicate on some protocol to a device capable of generating pulse signals for the pulsing unit. Buying any of these mentioned devices and trying to run them together off the shelf would be a bad idea. Configuring the devices individually to work together costs time figuring out how to do that and then time spent troubleshooting the seemingly inevitable issues that come along with that. This situation is suboptimal at best; How can we do better, so that we can continue to eat?

Eclipse

The Erdos Miller answer is to further integrate the devices we want to run within a more robust and capable system. The Eclipse system allows drillers to combine a directional and azimuthal gamma module into a single chassis and BUS. The combination minimizes a large number of potential equipment issues that can occur in extreme shock and vibration environments.

Eclipse collects data from the devices on its BUS and sends data the user asks for uphole via MudPulse and EM telemetry data. The paired Eclipse Touch software allows drillers complete and intuitive access to the functionalities of the system. Notably, Eclipse Touch also automatically determines the degree of certainty in the broadcasting tool's data.

Degrees of confidence are established by running over 100 filters in parallel and in real time on the incoming data. The filters that end up with matching data are grouped together. The grouped filter results, supplemented with their confidence percentages, vote and the dataset with the highest calculation of votes vs confidence is the accepted dataset. The user can see the results of this process in real time through the ‘Live’ tab (pictured top-left). A historical account is also available (pictured top-right).

We Strive to be Unstoppable

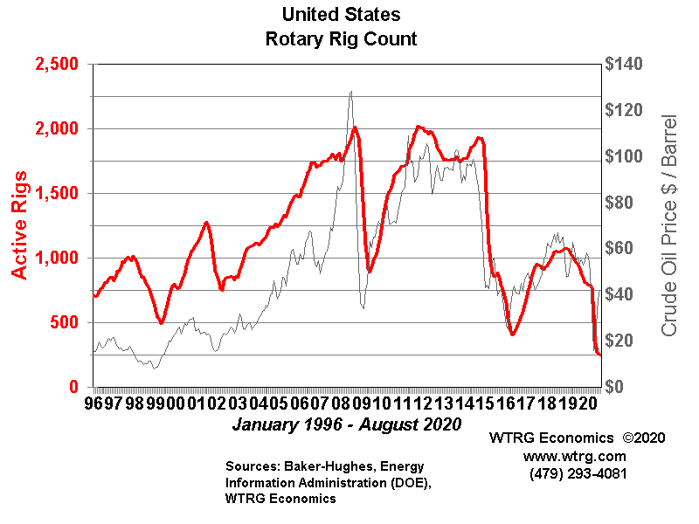

There were 791 crude oil and natural gas rigs in operation in the US as of January 2020[src]. The US Rig count has fallen to 255 as of September 19th 2020 [src]. The effects of geopolitical finagling between oil-producing countries and COVID-19 have decimated upstream oil and gas. When demand is low, demand is low and there is nothing that can stand against the power of economics. Low demand leads to a ruthless and competitive environment as soon as demand increases. What that will mean is that you only eat if you win. Efficiency in all aspects is instrumental to success. Having the most efficient technology is part of that and I believe we have that.

Thank you for your time,

Cameron Basham

Software Developer