Controlling a Drilling rig from 2000 Miles Away with LabVIEW

There is something special about drilling technology for me. It is a unique challenge that requires knowledge, talent, and trial and error. I often say that in Oil and Gas we have all of the requirements and expectations of sending a satellite into space, but just a tiny fraction of the budget given to NASA and nowhere near as many human resources.

It is hard to explain the feeling when you successfully design a new drilling tool, we get to control and drive some of the biggest and coolest machines in the world. Often, the process of creating the technology is so difficult and draining that when you finally see your creation come alive and work, you are too exhausted to even celebrate. It is often months or years later when you are reflecting on your experiences that you look back on what you achieved and feel great about your experience.

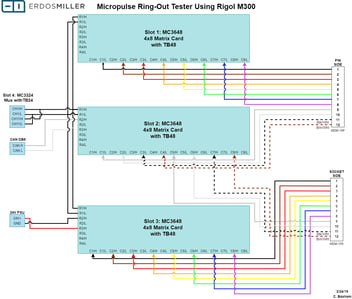

One of my favorite memories is working on an a new Drilling Rig Control platform a few years ago. Our client had formed a business arrangement with a Canadian company to deploy the new technology on rigs all over Canada. I was the primary developer for the program software and hardware. We had chosen to use the National Instrument's CompactRIO line of embedded controllers. The power of the having both CPU and FPGA at my fingertips, along with the huge variety of I/O modules makes the CompactRIO line an amazing set of tools for Getting-Things-Done.

It was my job to not only develop the embedded LabVIEW software that operated the Drilling Rig Control software, but to support it in the field as well. No deployment is ever perfect, and often there are few loose ends that need to get tied up. Sometimes things come up that no one could have expected, which to me seems to be par for the course for successfully deploying new technology.

I received a call sometime around 2 or 3 AM in the morning. Somehow issues with drilling technology never seem to crop up at convenient hours when you are wide awake and working. I picked up the phone and got a quick description of the symptoms of our ailing piece of drilling rig control technology.

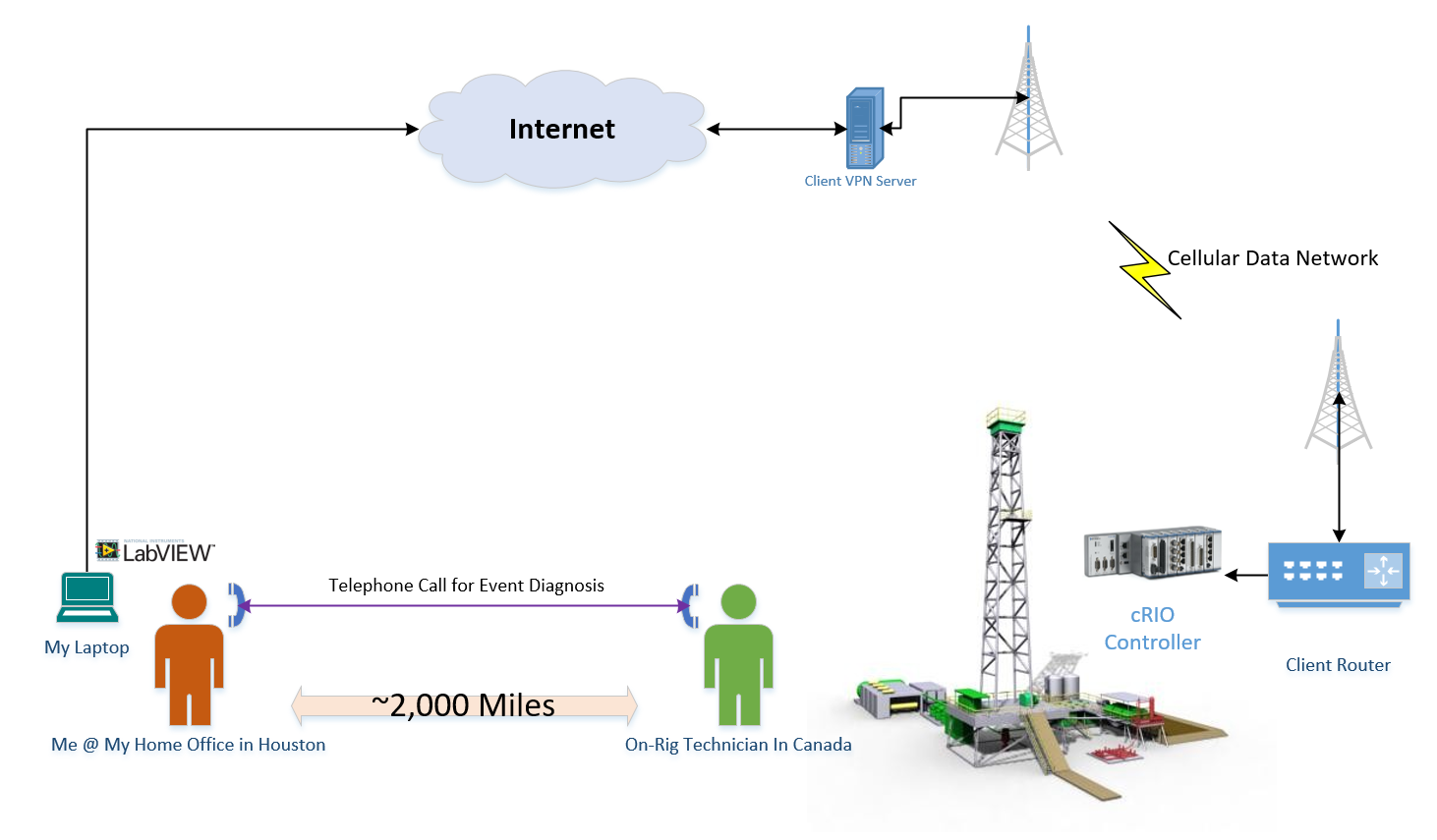

I took a few minutes to think about what the rig technician had described, and I came to a solution that I thought I could implement and deploy quickly. I crawled out of bed and over to my laptop. The Canadian organization we worked with had set up a great rig-to-rig cellular network with a VPN. We could get to any rig's network from anywhere in the world. So, from my home desk in Houston, Texas, I was able to connect into a VPN server located in Canada and gain network access that allowed me to reach out to the drilling site.

Luckily we had chosen to use the CompactRIO line of controllers from National Instruments as the basis for this platform. An amazing thing about the CompactRIO platform is that all of the development and debugging tools work over the network by default. This enabled me to remotely deploy the newly compiled solution to the target CompactRIO controller, which was physically installed into an industrial cabinet and deployed on a rig somewhere in Saskatchewan roughly 2000 miles from where I was currently developing.

With the solution developed and deployed, I called my Canadian counterpart back on his cell phone. "Are you guys ready?" I asked him, he took a minute to make sure the rig crew was prepared and the necessary safety checks perform. "Yes! We are ready when you are!" he said finally. The code already being deployed to the remote CompactRIO, all I had to do was hit the "Run" button and the Drilling Rig Control software would resume operating the drilling rig with the updated software.

I hit the LabVIEW "Run" button and off the code went executing on the CompactRIO thousands of miles away. The phone line was still open with the technician, and almost as soon as I hit the "Run" button I could hear all of the rig's heavy machinery, especially the large braking system of the rig, operating 2000 miles away in Canada in my earpiece. The audible feedback of the rig blew my mind as I realized that I had just hit a button from my laptop in Houston, Texas, and a rig somewhere in Saskatchewan, Canada had just come to life.

Ultimately, the fix worked, the rig crew was happy, and I promptly went back to sleep. This was certainly one of my favorite moments developing with National Instrument's LabVIEW, but not my only one.

About Erdos Miller

Erdos Miller guides and assists clients in the creation of advanced technology. Erdos Miller's clients are forward thinking companies that are never satisfied with the status quo and are always looking to challenge the expectations of what can be done.

To find out how Erdos Miller can help your firm develop and deploy advanced downhole technologies please visit the following links:

https://www.erdosmiller.com/services/electronic-device-development

A showcase of our Drilling Technology Work

To find out how Erdos Miller can assist you with monitoring or controlling your assets, optimizing your process, or enabling your existing technology to do more please visit the following links:

https://www.erdosmiller.com/services/labview-development-consulting

To find out how Erdos Miller enables customer success:

http://info.erdosmiller.com/case-studies