New Tools for MWD Applications: The FastCAP Ultracapacitor

At Erdos Miller, we specialize in turnkey electronic device development and process control and automation. We solve quality, reliability, production, and cost issues in existing devices and create new, market-leading products and processes for industry challenges – a huge component of our success and the success we pass on to clients is in the hardware and software we choose for each application.

In rugged electronics applications like measurement while drilling (MWD) in the oil and gas industry, hardware selection can either propel a solution to market-leading success, or devastate it. This blog post will discuss the various tradeoffs different power-generation hardware options for MWD applications.

Measurement While Drilling: An Overview

One critical function of MWD systems is navigation used for wellbore placement in the oil and gas industry. An MWD directional system allows users to track progress of a directional well during drilling (up, down, or to the side).

Developing technology in this industry requires understanding multiple engineering disciplines, using an iterative design processes, using advanced testing methods like highly accelerated life testing (HALT) and highly accelerated stress screening (HASS), and thorough field testing and validation. At Erdos Miller, our teams have spent a lot of time – over 100,000 man hours – designing high-pressure, high-temperature MWD systems and related rugged electronics hardware.

The Challenges of MWD System Hardware

To create a reliable MWD system, engineers have to build a rugged electronics solution that can operate at extremely high temperatures of >175 °C, withstand g-force of greater than 1,000 g, and endure vibration of more than 15 gRMS and pressure greater than 3,000 psi.

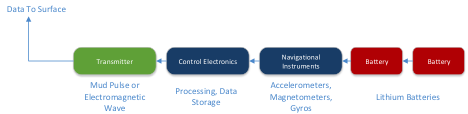

Because a main purpose of a MWD system is to facilitate navigation, its sensor data are critical to operators on the surface. To support the sensors, MWD systems require a power source, processor, and transmitter to power, analyze, and relay data to operators. This blog post will specifically focus on power sources for MWD applications.

Traditional MWD Systems: Lithium Batteries

Currently, MWD systems primarily use lithium thionyl chloride batteries, which contain energy-dense cells formed in to packs between 4’ and 6’ long.

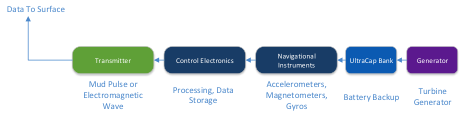

The following diagram depicts a standard Measurement While Drilling system:

A typical MWD system requires between two and six of these packs, which sell for about $1,000 each. In addition, these batteries also pose an explosion risk. They are so energy dense that when exposed to high temperature, pressure, or shock, they can explode. If this occurs during the drilling process, it can lead to millions of dollars of equipment loss, and an explosion during handling or transport could injure or even kill workers. The industry has sought to move away from these batteries but has not yet had a more reliable, cost-effective solution. Alkaline batteries are one option, and though safer, they cannot effectively operate at the high temperatures encountered by MWD systems and don’t prove useful for these applications.

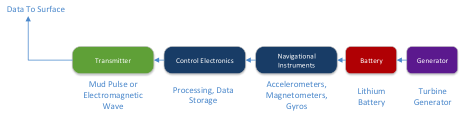

An Intermediary Solution for MWD Systems: Turbine Generators

Alternatively, an MWD system can include a turbine generator. Replacing one battery with a turbine generator as shown in the diagram below removes some of the disadvantages of lithium batteries:

These generators, created by companies like Turbine Dynamics, produce power using a simple alternator driven by the flow of drilling mud past an impeller. However, modern MWD systems must operate even while there is no drilling mud flow, so they still require at least one lithium battery, which comes with the disadvantages discussed above.

A New Solution for MWD Systems: The FastCAP Ultracapacitor

FastCAP Systems, a company with expertise in creating high performance ultracaps based on advances on the nanomaterial, electrolyte, cell construction and processing levels, just released high-temperature Ultracapacitors to the general market. These components will enable new designs not previously practically achievable, and they will undoubtedly find a home in many high-pressure, high-temperature, and other extreme environment systems.

The FastCAP Ultracapicitor brings the ability to pursue systems free of the dangers and costs associated with Lithium Batteries.

With the FastCAP Ultracapacitor, engineers can design a battery backup system that provides power when a generator cannot, as shown in the diagram below:

The system functions like a battery backup for a personal computer: when the drilling mud is flowing, the generator provides energy to the system. That energy both powers the system and charges the UltraCap bank. When the generator shuts down, the system draws power from the UltraCap bank. This won’t allow the system to run forever, but it will allow the system to run long enough until the drilling operation resumes and the generator can begin operating again.

With the FastCAP Ultracapacitor, we can now design turbine-driven MWD systems that can be entirely lithium-free. It adds an exciting new tool to high temperature electronics design, enabling systems that will be safer, smaller, easier to run, and far less expensive.

For more information about Measurement While Drilling (MWD) and creating rugged environment systems using the right electronic components to meet your challenge, contact us.

About FastCAP Systems

FastCAP delivers out-of-the-box, technology-based solutions to the toughest energy problems. From record-breaking energy storage devices for hybrid and electric vehicles, to game-changing solutions for energy exploration, every FastCAP team member is compelled to positively impact the way we produce, use and store energy.

http://www.fastcapsystems.com/

Resources

http://www.slideshare.net/VahidrezaBitarafhagh/mwd-projectgroup-new