Driving NPT to Zero. The Key to Reducing NPT

Drilling is a race against time. Every second spent waiting, troubleshooting, or recovering from failures is Non-Productive Time (NPT). It’s lost money, lost momentum, and lost opportunities.

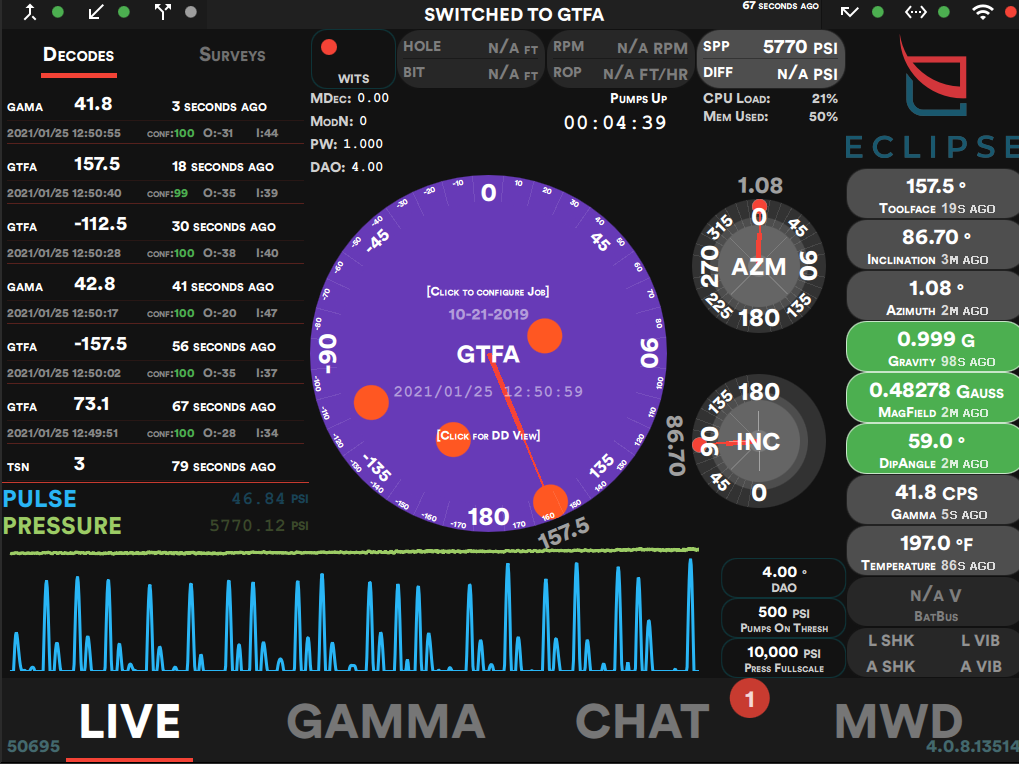

At Erdos Miller, we actively track reliability. We build tools to drive NPT as close to zero as possible. We achieve this by implementing features like Manual Sync, Automated Survey Corrections (ASC), and High-Speed Data Transmission, all built on a foundation of relentless reliability to minimize downtime and maximize drilling efficiency.

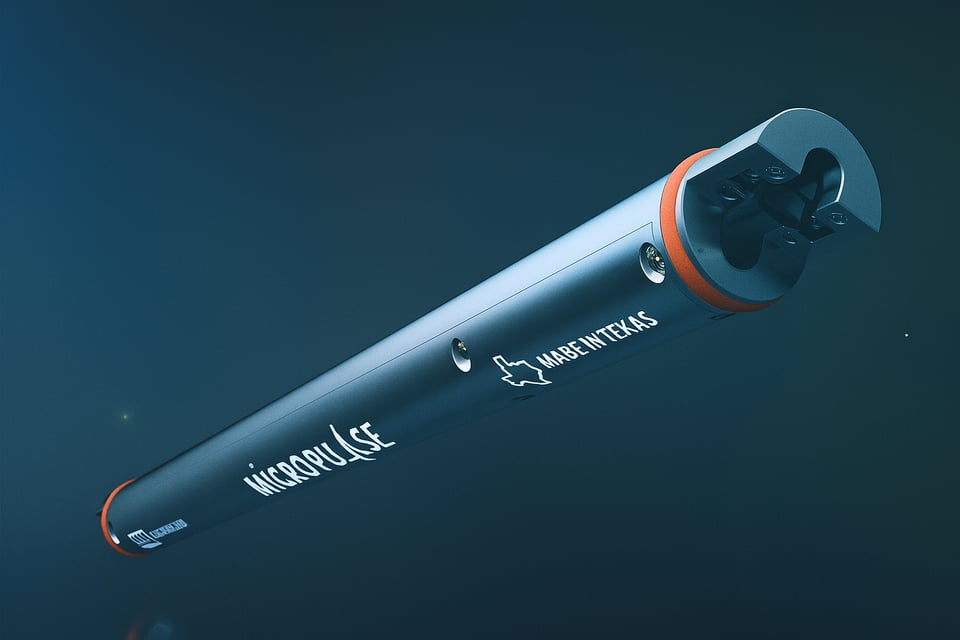

1. Relentless Reliability - Making Tools Bulletproof

Reliable tools mean fewer failures, less downtime, and more consistent operations. The best way to fight NPT is to prevent failures before they happen. Our bulletproof tools are engineered to withstand the extreme conditions of drilling —high temperatures, relentless vibration, and aggressive shock.

- We continuously refine our designs based on real-world drilling data to eliminate weak points before they ever become a problem. We over-design for extreme drilling to ensure that our tools:

- • Last longer

• Fail less

• Spend more time in the field

The result? Fewer unexpected breakdowns, fewer service interruptions, and more drilling.

2. Manual Sync - Saving Pump Cycles & Preventing Costly Delays

Our Manual Sync feature allows for continuous improvement in pump cycles, which directly reduces NPT.

In rare cases, the system may miss a sync pulse. Without Manual Sync, this would require stopping operations, cycling the pumps, and attempting another sync — costing you time and money.

In poor drilling conditions, Manual Sync can mean the difference between staying in the hole and pulling out for a costly trip.

Manual Sync allows customers to:

• Manually assist synchronization between the decoder and downhole tool

• Eliminate errors and pump cycling

• Ensure data transmission in weak signal conditions

• Save entire trips in challenging drilling environments

• Prevent costly delays

3- automated survey corrections (asc)

Reducing human error and enhancing efficiency

Historically, survey data was transferred manually, making it prone to human error. One mistyped number could lead to well-path deviations and operational delays.

With ASC on Eclipse Touch, manual entry is replaced with an automated API, integrating with MagVAR, Superior QC, and RoundLab for accurate, unbiased survey corrections.

ASC eliminates:

• Human error in data entry

• Manual data transfers

• Time wasted on troubleshooting

Corrections are now almost instantaneous, allowing teams to move forward without unnecessary delays, reducing NPT and improving efficiency.

4- High-Speed Data Transmission

When data transmission is slow, you wait longer for critical information, which leads to downtime and inefficiencies.

Our advanced decoding system processes pulses faster, providing real-time downhole data, so you can:

• Make decisions with confidence

• Avoid costly mistakes

• Reduce delays

Combined with advanced data compression, our system delivers faster, more efficient transmission for better drilling performance.

By continuously innovating in reliability, Manual Sync, Automated Survey Corrections, and High-Speed Data Transmission, we significantly reduce NPT for our customers.

Our commitment to minimizing downtime ensures that you keep drilling with confidence, efficiency, and cost-effectively. We remain resilient in our mission to provide tools you can count on—no matter what.

Author

Nathan Szanto - Engineering Manager

Contact us today to learn more.

Blog

RELATED BLOGS: