Case Studies

Our cost-effective solutions are customized to address client pain points and the

nuances of their industry and applications.

-TEStimonials -

This is the best decoder I have ever worked with; I really love the ET software!Chad Stanford | Total Directional

We have been with Erdos Miller for almost two years now and I can truly say this is the best team our company has ever worked within 20 years! If you're going to bed at night sweating bullets about your very costly developments then give these guys your projects and sleep well my friends - I do.Stuart McLaughlin | Magnolia R&D

EM is by far the best engineering team in Houston. From the top down this is a phenomenal organization. Came in under budget on several projects.David Gibson | Gibson Reports

Case Study # 1

Decreasing MWD survey transmission time by 56% and increasing overall MWD telemetry speed by 30% without increasing costs.

Challenge: Every minute spent waiting for surveys before drilling ahead adds up to hours of NPT over the course of a well. Reducing survey transmission time and increasing data density of measurements is an ever-growing request. Operators want to streamline drilling operations reducing NPT and increasing MWD data density.

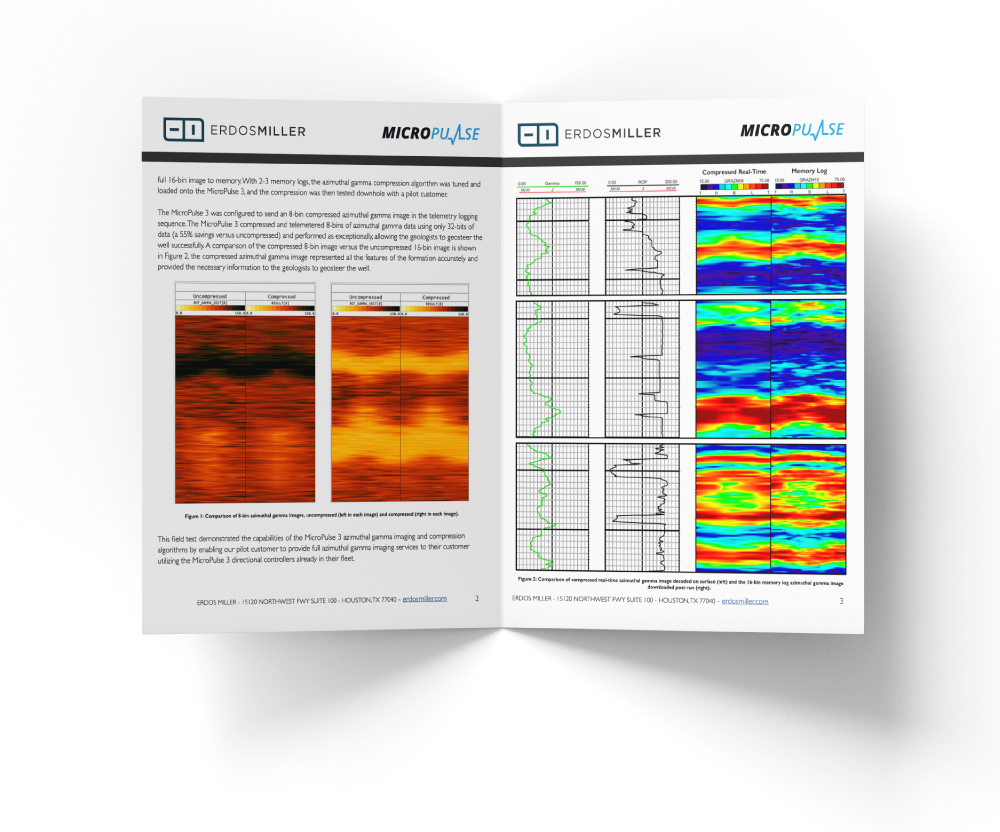

Case Study # 2 :MicroPulse 3

Reducing telemetry time by 64%-70% while providing higher image resolution using the MP3's Azimuthal Gamma Image Compression

Challenge: In a typical MWD system, telemetering 3-bins of gamma image data (with the left and right sectors mirrored) requires 27 to 33-bits, depending on the desired resolution. Telemetering 8-bins of uncompressed gamma data requires 72 to 88-bits, which would heavily affect telemetry times, update rate and image resolution.

Case Study # 3 :MicroPulse 3

.png)

MicroPulse 3: Continuous Inclination/Azimuth

Challenge: Evaluating the performance of continuous inclination and azimuth measurements is challenging, how do you know if what you are seeing is the actual wellbore shape, or noise, or algorithm artifacts? Can continuous inclination and azimuth measurements be relied upon for steering a well?