5 Must-Have Capabilities for Smart Rugged Devices

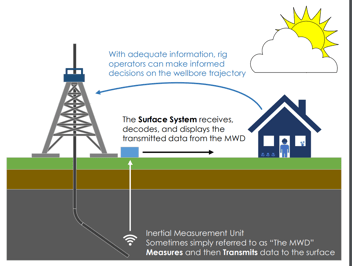

Simple tools left unchanged for decades are under increasing pressure year after year to do more. Rotating equipment is under pressure to inform their owners of exactly how much lifetime a unit has left before maintenance is required. Torque wrenches used in avionic assembly are under pressure to keep detailed track of every thread torqued and record the information to a central database. Rugged electronics like those used in Measurement While Drilling (or MWD) tools are under pressure to give operators a better idea of exactly what happens during the otherwise invisible drilling process. We keep expecting more performance and functionality out of our tools and it is likely that this trend will not change anytime soon.

Erdos Miller alleviates the pressure that many companies experience by empowering rugged electronics with advanced technology which allows clients to realize the increased expectations of their equipment. Achieving these expected results from technology driven tools requires more than a simple extension of the tool. Rather, high performing smart tools are the result of an entire ecosystem of components working in concert.

Here are the top 5 capabilities Erdos Miller recommends when building your smart Device EcosysTem:

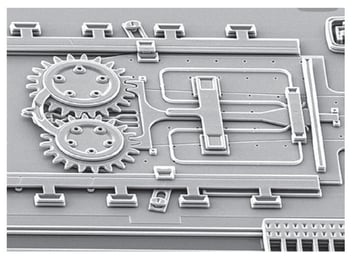

- Embedded Intelligence - For simple tools to become smart tools they need intelligence. The simple to smart tool transformation typically requires embedding computer technology directly into the physical product. Miniature circuit boards with processors, storage memory and battery systems are commonly attached during this embedding phase. The device is then programmed to be aware of its own operation and to record the parameters, under which it operates, to non-volatile memory. Smart devices can measure basic information such as operating conditions and battery voltage or they may compute more advanced measurements such as lifetime remaining. This type of complex measurement often require a large amount of historical data in order to build a model capable of computing such a measurement.

- Communications - Smart tools cannot operate in a vacuum. They need to transmit their data to the outside world where humans can use the data to take actionable steps. Smart tools must be connected and their data must be accessible. Recognize this trend? Many refer to this move toward connectivity and accessibility as the “Internet of Things”. In our work within the oil & gas, medical device and agriculture spaces, we typically refer to it as the “Industrial Internet of Things”. We have seen two patterns among data communication.

- Always Connected - These devices keep a permanent or near-permanent connection to the Internet or proprietary communications. Smart devices that operate near humans or near populated areas can utilize short-range wireless communications such as Wi-Fi or cell networks to report their data. Devices that need to be deployed in very remote locations away from urban areas or offshore typically utilize low bandwidth satellite communication to report critical operational factors.

- Touch and Go - Devices that operate underground such as drilling or mining tools will typically report their information in a “Touch and Go” pattern. In this situation, a device is deployed to remote work conditions that humans cannot access. While operating, the device records critical information to internal memory. When the devices are removed from the working conditions they can use wired or wireless tethering to transfer the recorded data to another system, which can then relay the information. The smart device memory is then typically erased and ready for another deployment.

- User Interface Software -

Interaction with smart devices needs to be simple and straightforward for humans. Intuitive user interfaces can help ensure the proper deployment and operation of critical equipment. Devices that are accessible to humans can have embedded touch screens that can allow for control of the smart device. Tools that must operate in harsh environments will use interface applications that will operate on a separate computer that can be tethered to a smart device. A good example of this would be how iTunes works with your iPhone. - Database Back End - It is surprizing how much data

can be generated by just a dozen smart devices operating in an industrial scenario. A strong database needs to be created in order to store and catalog all of the different parameters generated by smart devices. This database will produce a permanent location to store data and provide a common point of interface for analysis.

For cloud IoT integrations, we enable client's devices with daq.io which is a high-security system designed to protect your information in the cloud.

- Statistical Analysis, Business Informatics and Reporting - “Well, we have the data. Now, what do we do with it?” Finally, after all of the effort to design and manufacture a smart device, deploy that device in the field and then catalog the collected data, the real work can begin. The live, cataloged, and historical data can be used for any number of applications from improving tool performance and finding weak spots in the tool’s design, to improving the efficiency of a business; the applications are limitless.

There are multitudes of statistical software packages, business informations platforms and general data reporting tools that can translate data into a presentable format from rugged electronics. The most important thing to keep in mind is to use the data to create actionable steps for business improvement along the lines of the company goals. It’s all too easy and common to collect a mountain of data and then stare at it in awe of the creation without taking actionable steps to improve anything.

Erdos Miller will help you achieve business results and realize your potential by turning dumb devices into smart devices. Learn more at www.erdosmiller.com